Vertical Cracking Caused by Thermal Expansion at Bowls & Squash Club

The Problem

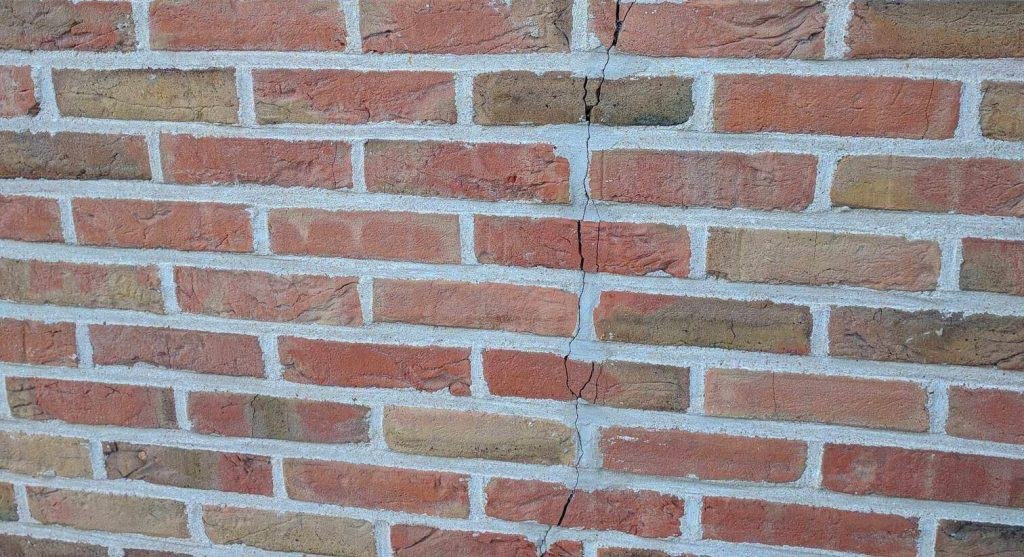

ASRS were contacted by a Bowls and Squash Club to provide a specification and repair method for vertical cracking caused by thermal expansion. The repair proposal was designed to restore the structural integrity of the masonry where cracking had occurred to the flank elevation.

ASRS discovered that thermal movement had caused vertical cracks in the outer masonry of the flank elevation. Thermal expansion and contraction is common in a long run of brickwork. Whilst thermal movement can be small, it can lead to serious cracking and other issues due to the open joints.

The Solution

ASRS specified the installation of a Helifix movement joints to rectify the problem. Introduction of a new movement joint offers substantial resistance to further cracking.

Before the movement joint was cut, Helifix Wall Ties were installed at 300mm c/c vertically, to bond leaves of masonry together. Installation of Helibar with Helifix Dry Fix Wall Ties has proven to be a successful method of masonry repair, when creating a movement joint. The Helibar was then bonded into the masonry with a de-bond sleeve loosely cover ing the other end of the Helibar, allowing the Helibar to move freely inside the sleeve. This ensures the masonry can expand and contract without cracking the masonry.

Backing cord was then installed into the cut joint and finished with mastic. Additionally ASRS replaced 23 cracked bricks with crack stitches installed to reconnect the cracked brickwork.

The structural repairs were completed within time and budget.

The Problem ASRS were contacted by a Bowls and Squash Club to provide a specification and repair method for vertical cracking caused by thermal expansion. The repair proposal was designed to restore the structural integrity of the masonry where cracking had occurred to the flank elevation. ASRS discovered that thermal movement had caused vertical cracks in the outer masonry of […]