Causes of

Lintel Failure

Lintel failure can be caused by a multitude of issues. Damage to concrete and timber lintels is often caused by damp and water ingress. Moisture can cause the steel reinforcement to rust in concrete lintels and the rotting of timber.

Structural movement is a cause of failure in all types of lintels, and the cause needs to be addressed alongside the lintel repair.

A common cause of failure on brick lintels, particularly in older buildings, is replacement doors and windows. Timber is a stronger and heavier material than PVC and added to the structural support provided by the lintel. PVC is unable to provide the same amount of support, adding additional stress on the lintel, causing it to fail.

Method of

Lintel Repair

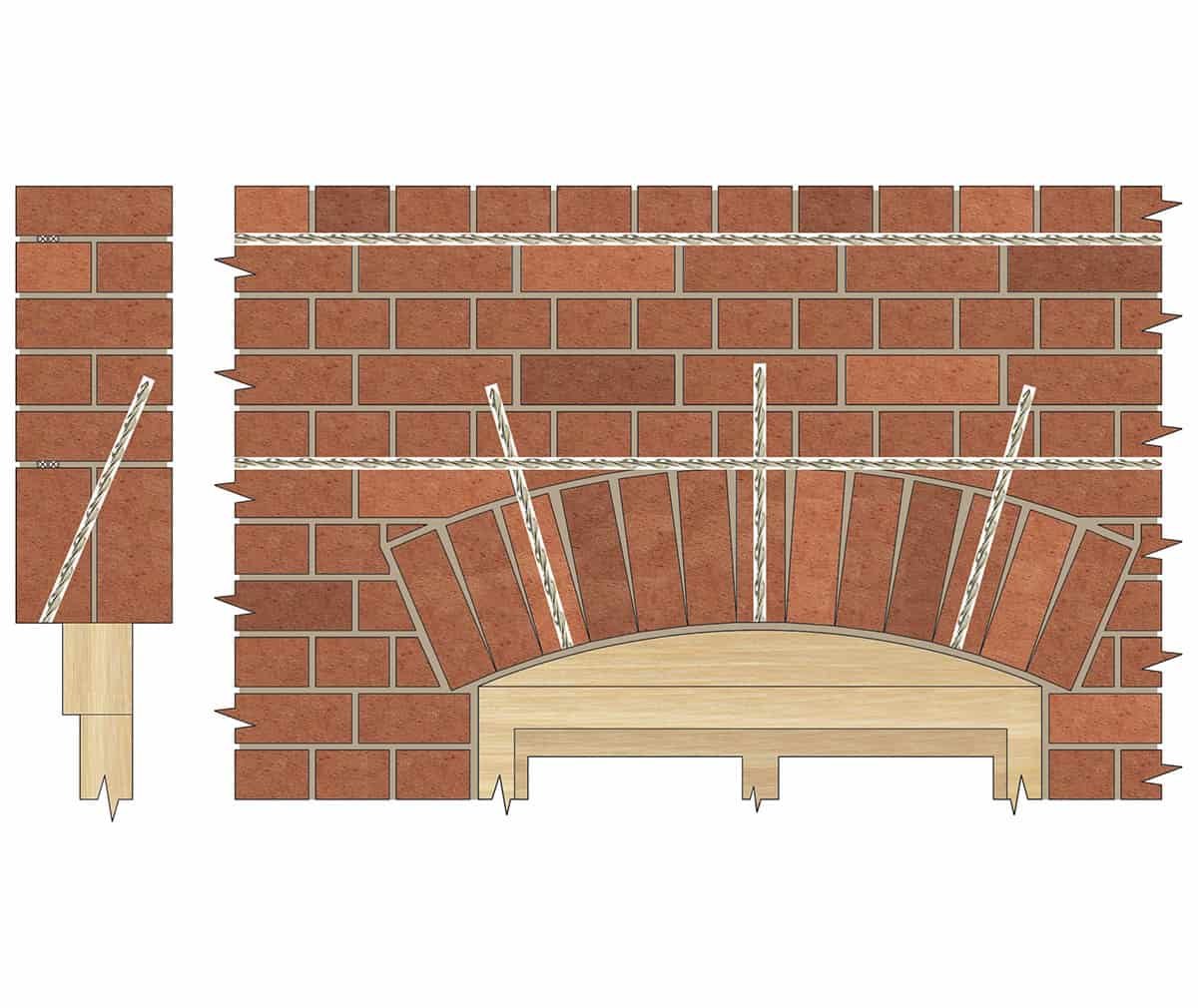

Lintel repair is most commonly executed using a combination of vertical pinning to reattach and reinforce any dropped masonry, and masonry beaming using the Helibeam system to redistribute the structural loads.

Pinning

Depending on the type of masonry, pinning is done either with DryFix or CemFix, stainless steel, helical ties. With a DryFix tie a pilot hole is drilled through the masonry, and the tie is the hammer drilled through the pilot hole. The high-profile fins on the tie self-tap into the masonry.

With a CemTie, a clearance hole is drilled into the masonry. The tie is then inserted using a grout filled pinning nozzle attached to a grout gun. As the cementitious grout is injected, the tie is carried with it to leave a fully grouted tie.

Masonry Beaming

Twin bands of long stainless-steel bar are inserted into pre-cut, horizontal slots in the bed joint at pre-determined intervals, and bonded to the masonry using cementitious grout.

As well as stitching any cracks, the masonry beams redistribute the structural loads across their width, easing the pressure on the opening below lintel.

Repairing

Brick Arch Lintels

Call us for help with any of these

Common structural defects, issues and problems

We offer free site visits to both domestic and professional clients to assess the problem and propose the appropriate repair programme, tailored to suit the specific needs of the project. ASRS are approved installers of the Helibeam System, offering cost effective, non-disruptive and concealed solutions to all aspects of remedial masonry stabilisation. Our skilled installation teams are trained and experienced in all aspects of masonry repair. They have been trained to the highest standard in every installation process to cover all H+S requirements. With most of our design and installation specifications we are proud to offer a 10yr indemnified guarantee on Helifix repairs and Micro Piling. We offer a 25yr guarantee for Wall Tie replacement.

Reasons

To trust ASRS

Free Quotation

Helifix Approved

Skilled Workforce

Guaranteed